Drywall Industry Issues and Solutions

- Lloyd "The Mud Slinger"

- Jan 30

- 1 min read

The construction industry has faced significant drywall installation problems since the 1970s, with repair costs sometimes reaching $75,000 for new homes that haven't even been occupied. Common failures stem from poor workmanship, requiring constant repairs.

Common Drywall Installation Failures:

Wrong board used, resulting in wavy ceiling and walls

Boards not properly screwed down

Over sheeted, under sheeted

Large gaps left unfilled

Seams not matched properly

Damaged board not trimmed out

Insufficient compound in seam centers

Corner bead barely glued on

Large gaps in corners

Corner bead barely covering drywall board

Wavy walls, ceilings and corners out of plumb and square

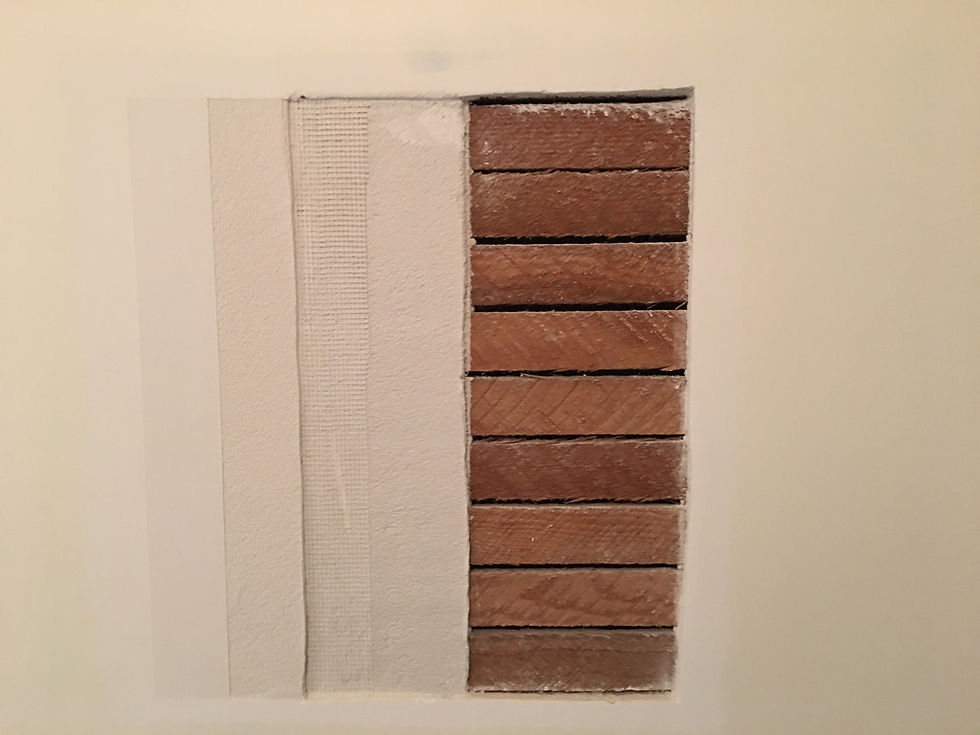

Heritage Plaster Work

Types of Plaster Systems:

Wood lath and plaster

Gypsum lath and plaster

Wire lath and plaster

Plaster Restoration Process:

1. Cover floors and trim

2. Clean and sand work areas

3. Prefill large cracks

4. Remove loose plaster that has lost keys

5. Bond all surfaces to be refinished and exposed lath

6. Base coat areas where basecoat was removed

7. Mesh cracked or damaged areas

8. Skim over mesh with plaster basecoat

9. Apply plaster topcoat

10. Prepare for paint and precoat all areas

Pre-Filling Guidelines:

Complete pre-filling before taping

Fill all gaps that show as black lines

Pre-fill damaged areas and trim out

Level cut edges to factory bevels

Fill corners square for bead work

Inspect pre-filling before proceeding with tape or bead work

Important note: For heritage plaster restoration, drywall compounds should not be used as they are incompatible with traditional plaster systems.

Comments